How to Choose the Right Thermocouple for Your Application

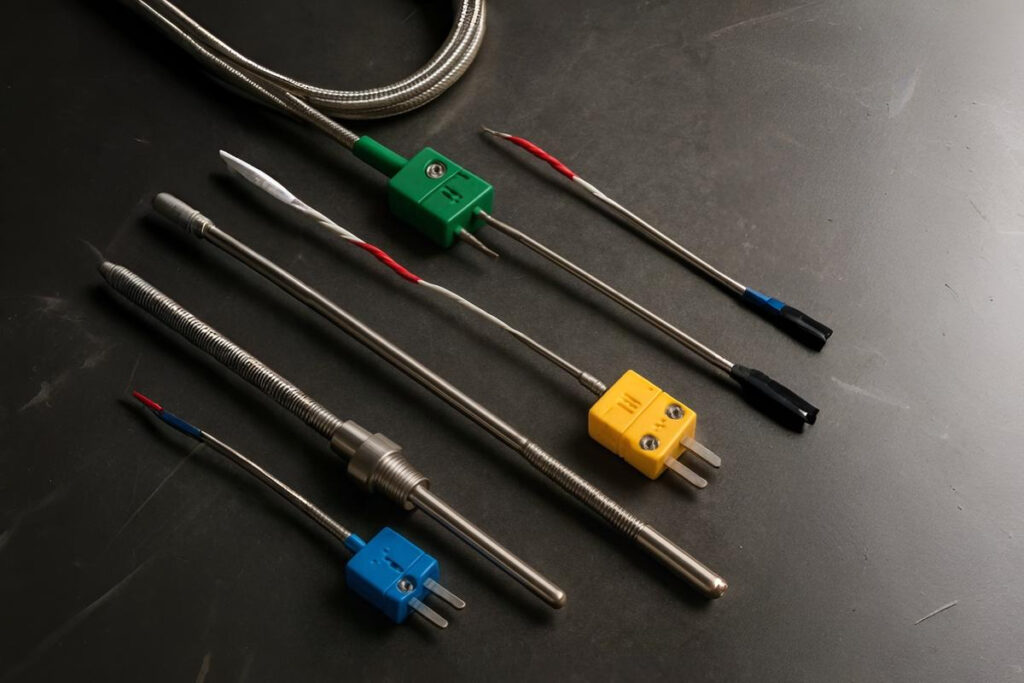

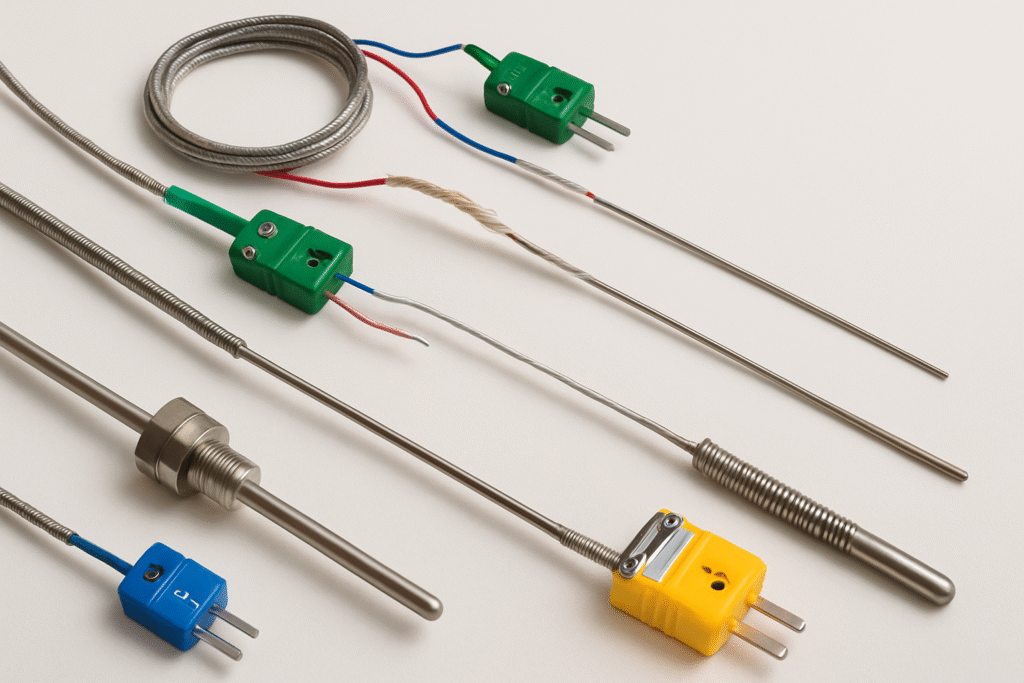

Introduction Selecting the right thermocouple is crucial for achieving accurate temperature readings and ensuring long-term reliability. Different industries require different sensor types, and choosing the wrong one can lead to errors, equipment damage, or inconsistent results.In this guide, we break down the key factors to consider before selecting the perfect thermocouple for your process. 1. Temperature Range Requirements Every thermocouple type supports a specific temperature range.For example: K-Type: -200°C to 1350°C (general industrial use) J-Type: -40°C to 750°C (vacuum & low-temp applications) N-Type: High stability at elevated temperaturesChoose based on the minimum and maximum temperatures in your environment. 2. Environmental Conditions Your operating environment affects the lifespan and accuracy of the sensor.Ask yourself: Is it corrosive? Is there vibration? Is moisture present? Is the atmosphere oxidizing or reducing? For harsh environments, metal-sheathed thermocouples offer better protection. 3. Response Time If your process involves rapid temperature changes, choose: Thin probe Exposed junction Minimal insulationFast response = Accurate control. 4. Accuracy Needs If high precision is required (like pharma or lab testing), select a thermocouple with: High-stability alloys Proper calibration Suitable junction type (grounded or ungrounded) 5. Compatibility With Instruments Ensure your thermocouple is compatible with: Temperature controllers PLCs Data loggers Transmitters K-Type is the most universally supported option. 6. Budget Considerations Cost varies by thermocouple type: K-Type → Affordable & durable N-Type → Slightly expensive but very stable E-Type/T-Type → High signal strength for low temperatures Choose based on performance vs. budget needs. Conclusion Selecting the right thermocouple depends on understanding your temperature range, environment, accuracy demands, and system compatibility. The right choice ensures long-term reliability, safer operations, and better performance across all industries.